Cypress wood as the basis

Shou Sugi Ban is a special charring technique inspired by a centuries-old Japanese tradition. With Shou Sugi Ban (‘burnt cypress’), pine wood is burnt on one side by tying three planks together into a chimney and lighting a fire at the bottom. This creates a high temperature and low oxygen in the “chimney”, creating a beautiful charred layer on the wood.

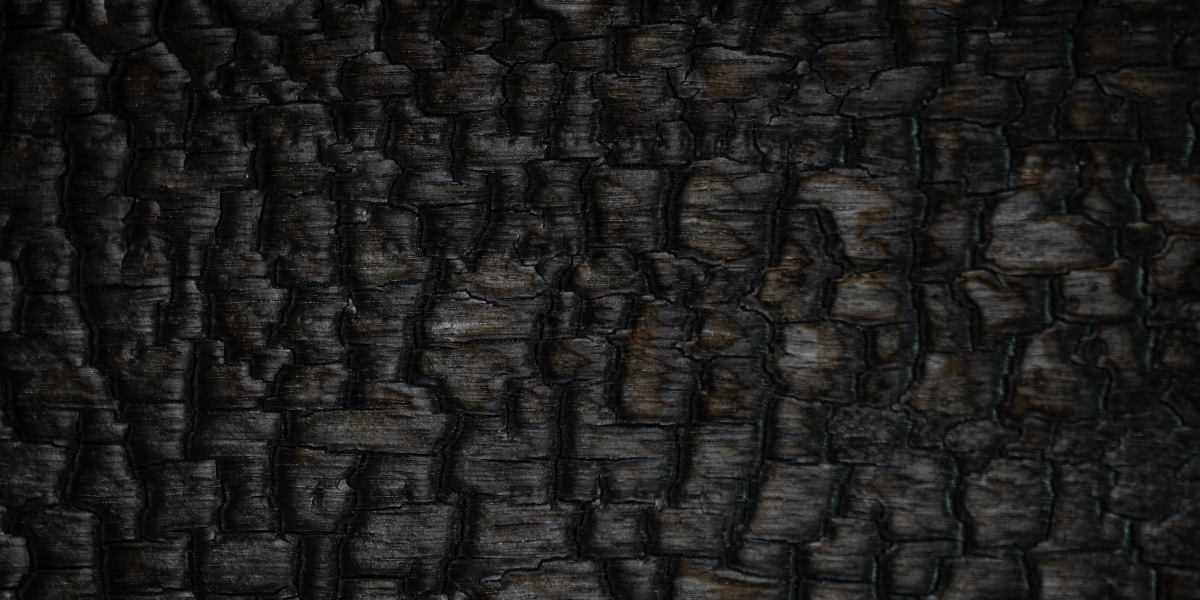

The primal power of the fire remains visible in the colour and texture of the wood after burning. This is why all Shou Sugi Ban processed wood species have their own texture and applications, both aesthetically and constructionally.

You will discover which types of wood these are in the Zwarthout l Shou Sugi Ban sample box.

Traditional Shou Sugi Ban in steps

Traditionally, cypress wood was used followed by a process consisting of a number of steps:

- Drying: After the wood is cut and sawn, it is first dried for a period of time to reduce the moisture. By drying the wood, it can be burned more equally.

- Planing and sanding: When wood has just been cut, it is not flat. Therefore, the wood is planed and sanded to create flat surfaces. This not only makes it more usable, but also makes the outcome of the firing process more predictable.

- Burning: Burning the wood is one of the most important parts of the Shou Sugi Ban technique.

This involves exposing the wood to excessively high temperatures with little oxygen, charring the surface very gently, evenly and in a controlled manner. The intensity and duration of burning varies depending on the type of wood, the time, temperature and proper cooling after burning. It is a process that varies for each specific plank and is assessed with each plank. The fire masters at Zwarthout l Shou Sugi Ban strive to strike a balance where the charring gives the wood sufficient protection without losing its structure and integrity. This requires real craftsmanship.

- Cooling: After burning each plank, the charred wood is cooled immediately. Cooling the burnt planks keeps the charred layer strong.

- Post-treatment: Post-treatment of the charred wood, is done for a brushed or fixed variant. With a brushed variant, the char layer that has just been burnt is brushed away. This creates a flame pattern. Finally, an oil or water-based stain is applied to protect the brushed wood. A second post-treatment is fixing. Fixing is done when the wood is used indoors. Fixation provides a protective layer, which reduces the burnt wood’s emission.

Shou Sugi Ban requires an eye for craftsmanship and detail

Applying the traditional process of Shou Sugi Ban requires craftsmanship and an eye for detail. Controlling and ‘mastery’ of the charring process is essential to achieve the desired aesthetics and durability without damaging the wood in the process. The key is control over the intensity and duration of the process, in addition to good preparation. Although modern technologies and equipment are sometimes used to make the process easier or cheaper here and there, the authentic character of Shou Sugi Ban is retained in many applications. The craftsmanship of charring is a process that takes years to fully master.

Shou Sugi Ban at Zwarthout | Shou Sugi Ban

At Zwarthout | Shou Sugi Ban, we try to respect the traditional Shou Sugi Ban as much as possible. Our charring masters are true craftsmen who burn the wood a self-developed furnace. We apply the technique to different types of wood, each with its own look, character and properties. Discover the possibilities for the interior or exterior of your home or project in our sample box.