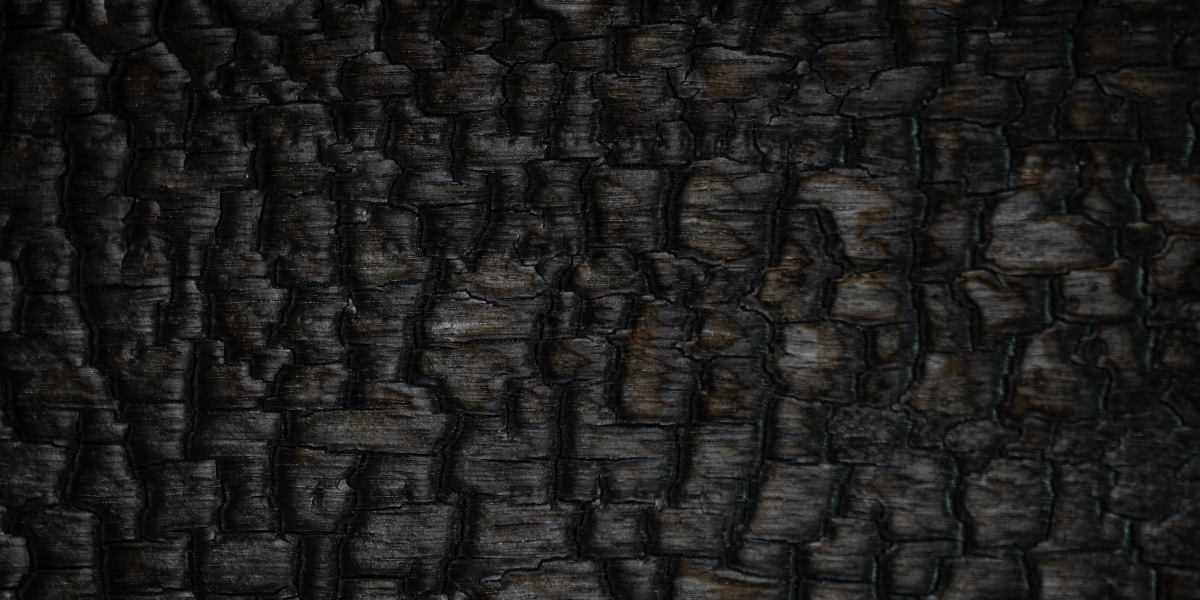

The Shou Sugi Ban technique is an ancient Japanese technique of burning wood to create a beautiful charred layer on the surface of the wood. This technique is also known as Yakisugi.

Zwarthout | Shou Sugi Ban has developed this ancient technique by combining an old-fashioned craftsmanship with modern technology. This results in high-quality charred wood.

In this blog, we will explain step by step how high-quality Shou Sugi Ban wood is made.

High-quality Shou Sugi Ban

To make high-quality Shou Sugi Ban wood, several aspects are important. First of all, the wood must be suitable for this technique. Not all types of wood are suitable for the Shou Sugi Ban process. Wood like larch and spruce get a very soft charred layer that will quickly disappear from the planks due to rain and wind. Over the past 13 years, Zwarthout | Shou Sugi Ban has tested several wood species for quality.

The result: 5 species are included in the collection that meet all requirements. These are Accoya, thermally modified woods such as Fraké and Radiata Pine, Douglas fir and Moso bamboo X-treme.

Quality difference: furnace and hand burner

The Shou Sugi Ban process involves a high temperature combined with low oxygen, so it is important to get a solid charred layer that sticks to the wood, that gives off little and does not smell.

If the temperature is too low, a shallow charred layer will form and give off a lot of soot. With too much oxygen, the wood molecules will burn too much, creating ash resulting in a soft char layer.

Burning at home with a hand burner is therefore not really an option. The temperature remains far too low and there is too much oxygen present, so the planks will turn black, but give off a lot of soot and will have a very soft charred layer.

The parameters for consistent quality

Actually, the Shou Sugi Ban technique is a combination of the ‘burning’ and ‘degassing’ wooden planks. This is also known as pyrolysis and is the technique of creating a high quality charcoal layer . The parameters used are a temperature of over a thousand degrees Celsius, low oxygen level in the oven, time and proper cooling. For each type of wood and each batch, the control is different to eventually get a consistently high quality Shou Sugi Ban plank. The goal of high quality Shou Sugi Ban wood is to produce a hard, pure charred layer that is firmly attached to the wood underneath.

Shou Sugi Ban planks charred in the furnace of Zwarthout | Shou Sugi Ban are black and stay black because the char layer is UV-resistant. Thus, low maintenance is required to keep the wood black. In addition, the planks give off a little.

Creating high-quality Shou Sugi Ban wood requires craftsmanship, attention to detail and proper technique. By carefully choosing the right wood species, burning the wood in a controlled manner, you can create a product that is not only sustainable, but also visually impressive. With the right approach and materials, Shou Sugi Ban adds a unique, timeless aesthetic and functionality to any space, whether interior or exterior.